A chimney flue is a vertical passage used for the exhaust gases produced by fireplaces, wood-burning stoves, furnaces, and other solid fuel-burning appliances. It carries smoke, gases, soot, and ash out of the building.

We’ll explore the different types of chimney flues and their anatomy. We’ll also delve into the problems that arise with chimney flues and highlight the essential maintenance practices to ensure their proper functioning.

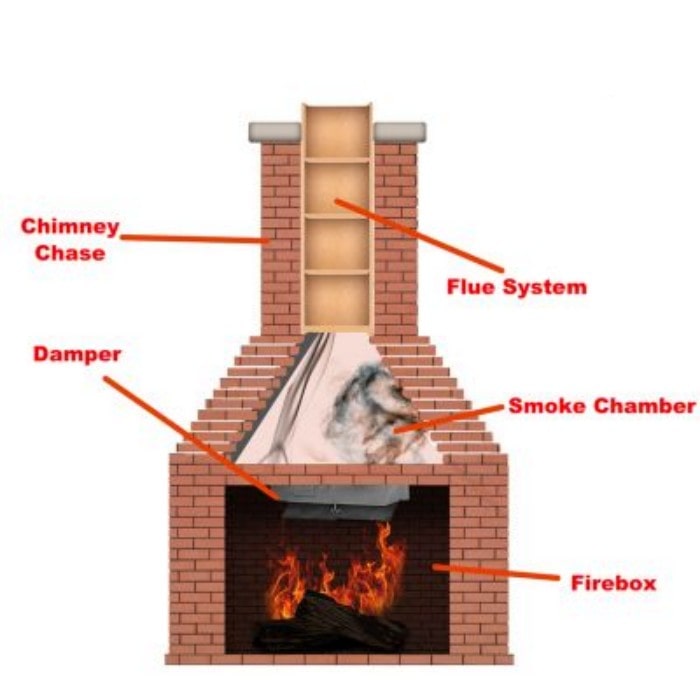

Anatomy of a Chimney Flue

The chimney flue is integral to a fireplace or woodstove’s proper functioning and safety. It ensures the efficient removal of combustion products and assists in the combustion process by providing oxygen to the fire. The flue’s draft promotes upward airflow, preventing smoke and gases from flowing back into the room instead of being expelled outside.

Additionally, regular use of a chimney flue helps minimize creosote buildup by providing a pathway for the gases to escape efficiently. This reduces the risk of chimney fires because creosote is highly flammable.

A. Description of the Different Parts of the Chimney Flue

Understanding the anatomy of a chimney flue provides valuable insight into its components and how they work together to operate fireplaces or woodstoves efficiently.

1. Flue Liner

The flue liner is the innermost layer of the chimney flue. It serves as a protective barrier by preventing the combustion byproducts and gases from seeping into the chimney walls. Flue liners are commonly made of clay tiles, metal liners, or cement.

2. Smoke Chamber

The smoke chamber is the area directly above the firebox or combustion chamber of the appliance. Its primary function is to efficiently channel the smoke and gases the fire produces into the flue.

The shape of the smoke chamber is typically tapered, narrowing as it rises toward the flue. This shape helps accelerate the flow of smoke and gases upward.

3. Flue Collar

The flue collar is the connection point between the fireplace or woodstove and the chimney flue. It’s typically a metal collar that attaches directly to the appliance’s exhaust outlet. It ensures a secure alignment between the appliance and the flue.

4. Flue Damper

The flue damper is a portable device located at the top of the flue or within the flue collar. You can open or close it to control the airflow and draft within the flue. The flue damper helps regulate the heat loss from the appliance. It also prevents downdrafts when the appliance is not in use.

5. Chimney Cap

The chimney cap is a protective covering or hood installed on the top of the chimney flue. It serves multiple purposes, including preventing rainwater, debris, and animals from entering the flue while allowing proper ventilation.

B. Materials Commonly Used to Construct Chimney Flues

The construction of chimney flues involves a broad array of materials.

1. Clay Tiles

Clay tiles have long been a popular choice for chimney flue construction. They offer excellent heat resistance, durability, and insulation properties. Clay tiles are capable of withstanding high-temperature and can effectively contain and direct the flow of combustion byproducts.

2. Metal Liners

Stainless steel and other metal liners are often utilized in chimney flue construction. These liners are highly corrosion-resistant, making them suitable for various heating appliances. They provide a smooth and efficient passage for exhaust gases.

3. Concrete

Concrete flue liners are typically made from refractory concrete, formulated to withstand high temperatures and the corrosive effects of combustion byproducts. Its insulation property prevents excessive heat transfer to the surrounding masonry and contributes to the overall efficiency of the chimney system.

4. Composite Materials

Composite materials are innovative materials that combine different components to create a single, enhanced material with unique properties. One example of a composite material used in chimney construction is ceramic fiber liners. Ceramic fiber is a lightweight material made from ceramic and other reinforcing fibers.

Composite materials offer exceptional insulation properties, highly effective at containing and directing heat flow within the chimney flue. They’re also highly resistant to thermal expansion and contraction, which can occur inside the chimney flue due to extreme temperature changes.

C. Design Variations Based on the Type of Heating Appliance

Different heating appliances produce varying heat levels and combustion byproducts and require specific venting requirements. We’ll explore the design considerations for chimney flues based on the type of heating appliance.

1. Fireplaces

Chimney flues designed for fireplaces typically feature a larger size and specific dimensions to accommodate the larger volume of smoke and gases produced by wood-burning or gas-burning fireplaces. The design may incorporate a smoke chamber and a damper system to regulate the airflow and control the draft.

2. Wood-Burning Stoves

Wood-burning stoves provide efficient heating and are known for their high heat output. Flue design for wood-burning stoves focuses on efficient combustion and draft control.

The flue may include insulation to minimize heat loss and ensure proper venting of the smoke and gases generated by burning wood. The design may also incorporate a baffle system to optimize fuel efficiency.

3. Gas Furnaces

Gas furnaces are commonly used for central heating systems. Chimney flues for gas furnaces are designed to safely vent combustion byproducts, such as carbon monoxide. They often feature airtight connections and insulation to prevent heat loss.

4. Solid Fuel-Burning Appliances

Chimney flues serving other solid fuel-burning appliances, such as pellet stoves or coal-burning furnaces, require specific design considerations. These appliances have unique venting requirements because of the characteristics of the fuel and the combustion process.

The flue design may incorporate ash traps, secondary combustion chambers, and catalytic converters.

Types of Chimney Flues

Chimney flues have different types, each with its characteristics and benefits.

1. Single-Wall Flues

Single-wall flues are typically constructed using a single material, such as stainless steel or clay tiles. The size of such flues depends on the heat output and flue gas volume.

This type of flue generally doesn’t have built-in insulation. This can cause heat transfer to the surrounding building materials.

2. Double-Wall Flues

Double-wall flues are constructed using two layers of materials, typically with an inner layer and an outer shell. The inner liner conveys the combustion products, while the outer shell provides insulation and a protective barrier.

The insulation between the inner and outer walls reduces the external temperature of the flue, reducing the risk of accidental contact. This makes double-wall flues safer than single-wall flues.

3. Insulated Flues

Insulated flues consist of two concentric layers; an inner liner and an outer shell with insulation material filling the space between them. The insulation material helps to reduce heat transfer, to improve energy efficiency, and to prevent excessive temperatures on the outer surface of the flue.

Additionally, the added insulation material makes insulated flues safer than single- and double-wall flues.

4. Masonry Flues

Masonry flues are built by laying bricks or clay tiles in a specific pattern to create a passageway for the combustion products to exit the building. The bricks or clay tiles are typically held together with mortar, forming a solid and durable structure.

This chimney flue isn’t as effective in providing insulation as an insulated flue. But they can offer long-lasting durability because masonry materials are known to withstand high temperatures.

5. Stainless Steel Flues

Stainless steel flues are highly resistant to the corrosive effects of flue gases and moisture. This prevents degradation of the flue system over time.

Furthermore, they can withstand high temperatures generated by various heating appliances. This quality makes stainless steel flues suitable for wood-burning stoves, fireplaces, and other solid fuel-burning appliances.

Common Problems With Chimney Flues

Chimney flues can experience problems over time, affecting their performance, safety, and functionality.

1. Creosote Buildup

Creosote buildup is the accumulation of a sticky, tar-like substance called creosote on the inner walls of a chimney flue.

In its worst state, creosote becomes a hardened and glazed deposit that can be extremely challenging to remove. It poses a severe fire hazard as it acts as a fuel source, potentially leading to chimney fires.

2. Blockages

Blockages can occur at various points within the flue, including the chimney cap, flue opening, or smoke chamber.

If the chimney flue lacks a cap or is damaged, leaves, twigs, and other organic debris tend to accumulate, restricting airflow. Additionally, nesting animals, such as birds and squirrels, can construct nests inside the flue during nesting seasons, posing a significant risk of blockage.

3. Cracks and Leaks

The chimney flue can develop cracks over time because of the effects of heat, moisture, and aging. These cracks might allow gases and heat to escape through the chimney walls.

Moreover, they can also allow water, debris, or small animals to enter the chimney flue, leading to potential damage or blockages.

4. Structural Damage

Structural damage in chimney flues can result from aging, excessive heat, weather elements, or shifting of the building foundation. It can weaken the chimney flue’s ability to withstand external forces, such as high winds or seismic events, increasing the risk of collapsing the chimney.

5. Fire Hazards

Accumulating combustible deposits such as creosote on the chimney flue’s interior walls is a significant concern. Poor ventilation can result in incomplete combustion and the release of unburned fuel particles, contributing to creosote buildup.

Blockages inside the chimney flue can cause smoke backup and potential chimney fires. Cracks and deteriorated masonry can provide pathways for heat and sparks to reach combustible materials, heightening the risks of fires.

Maintaining and Repairing Chimney Flues

Prioritizing the upkeep of your chimney flue is paramount to ensure a safe and efficient fireplace experience.

1. Regular Cleaning and Inspection

Chimney flue can accumulate combustible deposits such as creosote, soot, and debris over time. Regular cleaning minimizes these deposits.

Chimney professionals can identify cracks, gaps, or deterioration in the flue lining or masonry. They can also uncover safety issues like loose or damaged components or faulty connectors. Timely detection of these issues enables prompt repairs, preventing further damage or accidents.

2. Chimney Sweep Services

Chimney Sweeps are trained professionals who specialize in thoroughly cleaning chimney flues. They use specialized tools to eliminate creosote, leaves, and other debris in the chimney, ensuring efficient operation.

Additionally, they may suggest measures to reduce creosote buildup, improve ventilation, or enhance the efficiency of the chimney system.

3. DIY Repairs

Assess your skills and knowledge level with DIY projects. Understand that certain chimney repairs may need specialized expertise and equipment. Complex structural problems or extensive damage are best left to professionals.

If you’re unsure about your abilities, it’s recommended to consult a professional chimney technician.

If you go for DIY, ensure you have basic safety equipment, such as a dust mask, goggles, and gloves. Moreover, beware of any potential hazards, such as working at heights.

Lastly, comply with local building codes and safety guidelines for your chimney flue’s safety and proper functioning.

4. Professional Repairs and Replacements

Professional chimney technicians have the knowledge, training, and experience to assess your chimney flue’s condition accurately. They can identify underlying and structural problems that may not be readily noticeable to an untrained eye.

They’re also well-versed in local building codes and regulations. Hiring professionals assures you that your chimney system adheres to the required guidelines.

Though professional repairs and replacements might involve an upfront cost, they can save you time and money in the long run.

Conclusion

The chimney flue enhances the overall safety and functionality of the fireplace or wood stove.

It facilitates the efficient removal of combustion products while supporting the combustion process by supplying a steady oxygen flow to the fire. With its draft promoting upward airflow, the flue ensures that the smoke and gases are expelled outside rather than entering the room.

Don’t wait until issues arise. If you notice problems with your chimney flue, address them immediately by hiring a professional chimney technician. Additionally, schedule annual inspections and cleanings by a professional chimney sweep to identify potential problems and eliminate creosote buildup.

Take proactive steps and fulfill the necessary actions to ensure your chimney flue remains in excellent shape.